Setting up new work equipment

Summary

- Add safety standards

- Add work equipment

- Assign work equipment to work positions

- Enable employees to select work equipment sizes

- Automation will daily check for missing equipment for employees

- Trigger distribution work equipment to employees at workflow approval page

- Automation will hourly check if work equipment stock is available and will trigger rebooking and reservation

- if no stock, purchasing department gets requirements in their existing views

- Once reservation is completed, department lead will get task to pickup work equipment and deliver it to their team

- Once task completed, work equipment will be written off

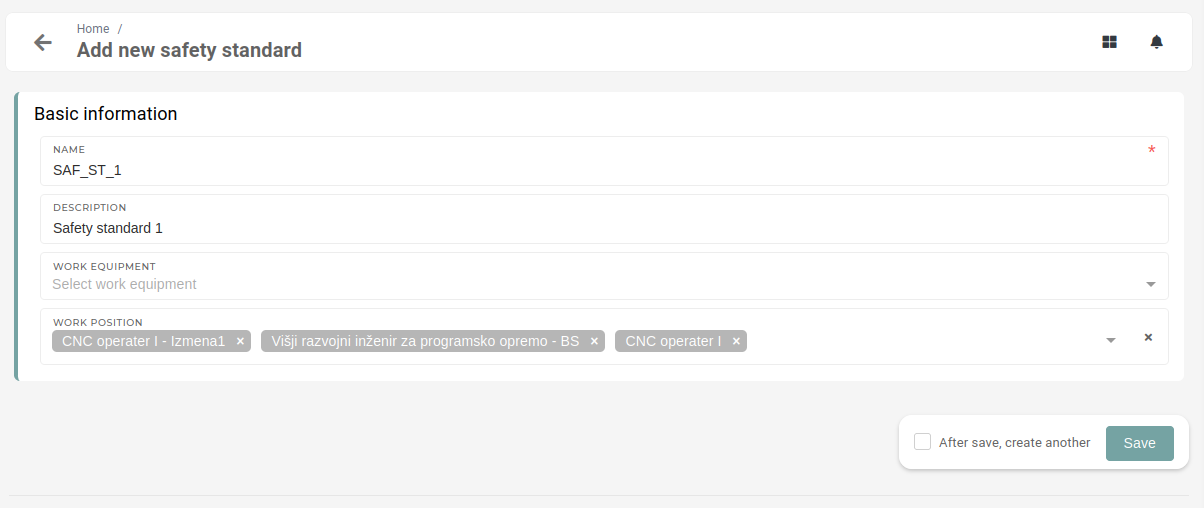

1 - Add safety standards

This action requires the "create safety standard" permission.

If it does not already exist, a safety standard need to be created for selected work positions.

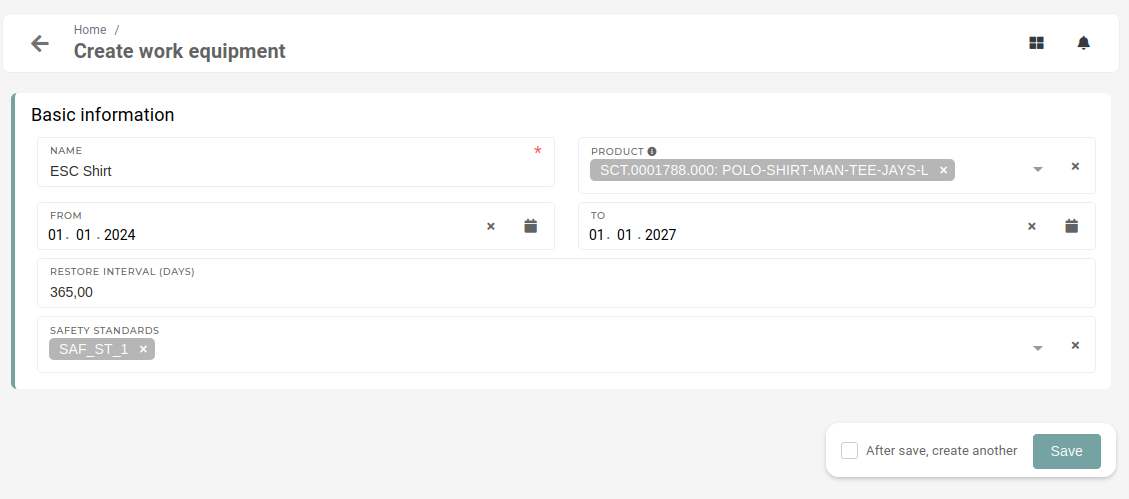

2 - Add new work equipment

This action requires the "create work equipment" permission.

To add new work equipment, click on the create button on work equipment table or go to the work equipment create form.

A new work equipment requires a unique name, that distinguishes it from other work equipment.

After a name is entered, product(s) of type Protection products must be selected. These products will be what the work equipment represents. Usually, these products are different confection sizes of the same product.

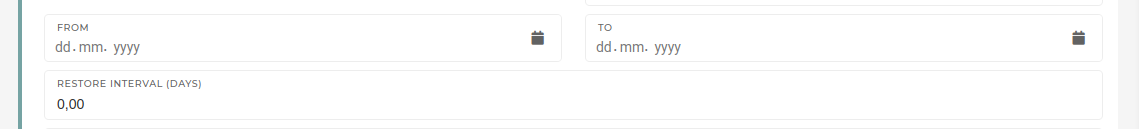

Enter the "From" and "To" dates to define how long the work equipment is valid to be distributed.

The "Restore interval" is used to set the renewal period or amortization interval in days (eg. every 365 days, employees receive new equipment).

The safety standard(s) that correspond to the new work equipment need to be selected. Through these, work equipment is assigned to work positions.

Work equipment is connected to work positions through safety standards.

3 - Assign work equipment to work positions

This action requires the "update work position" permission.

The created new work equipment now needs to be assigned to work positions. This is done on a selected work position from the work positions table.

On a work position, we first need to select a safety standard (if it is not already selected). We then enter its quantity and then click "Add new" to add a new work equipment for this work position.

Only work equipment of the selected safety standard(s) will be listed.

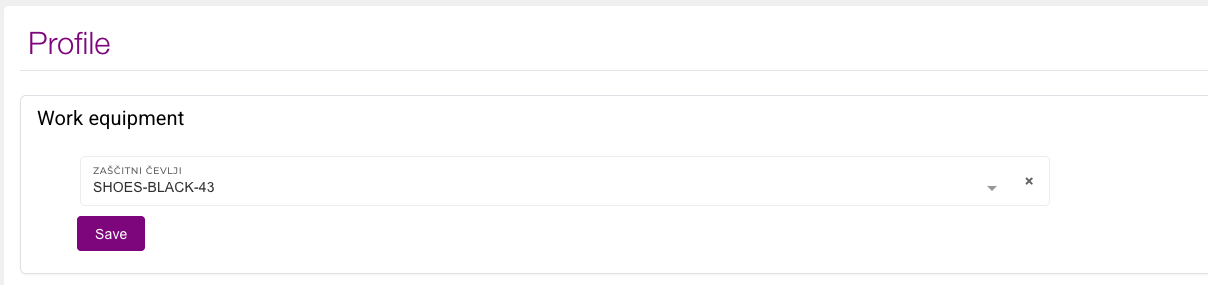

Once work equipment is selected on work position, users with that work position will be able to select confection numbers of their equipment on their user profile page under the "Work equipment" section.

Users can edit their equipment confection numbers when option "Allow editing confection numbers" is enabled.

Once employees have selected/updated their equipment confection numbers, the option must be disabled.

4 - Work equipment distribution

An automated process is used to check for missing equipment of employees on a daily basis.

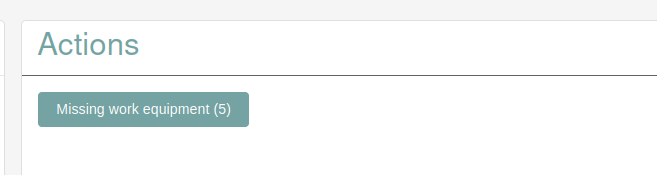

Work equipment distribution can be triggered from the "workflow approvals" page with the "Missing work equipment" button.

When missing work equipment without stock is found, the missing quantity is added to purchasing requirements, to be handled by the purchasing department.

The distribution process will run a hourly check, if work equipment has available stock, at which point it will trigger rebooking and reservation tasks.

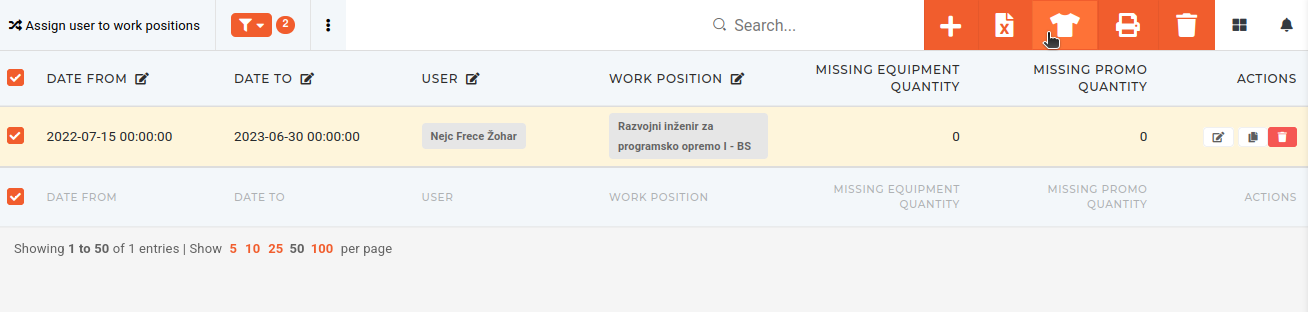

Work equipment requirements can also be managed manually on the "Assign user to work positions" page.

Here, you can click the "shirt" button to "start work equipment distribution" work equipment to users.

5 - Getting work equipment to employees

The task of getting work equipment to employees is handled by department leads.

Once reservation is completed, leads of departments will get tasks to pickup work equipment and deliver it to their team. When work equipment is handed off to employees and the task is completed, work equipment will be written off.